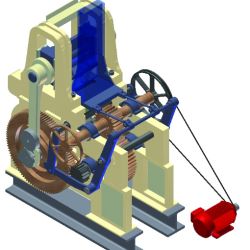

RE-PRESS M/C’s FOR EXTRUDED BRICK AND TILE BLANKS

- Single or double machines independently driven and fed with extruded brick or tile clods.

- Continuous running when pressing with automatic feed motion or can be operated manually to produce special shapes and sizes including cable covers.

- Eccentric pushing and stopping motion arrests press at top of each stroke to allow removal by hand if required.

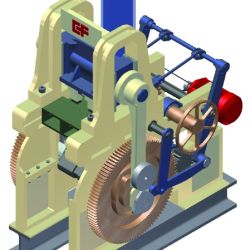

STIFF PLASTIC GRANULAR FEED BRICK & PAVER PRESS

- Accepts semi dry granular material.

- Two bricks pressed simultaneously.

- Two stage double pressing action creates strong dense bricks.

- Fully automatic feed and discharge via cams and eccentric action.

- Simple easily maintained mechanical technology with low power input.

FRICTION SCREW PRESSES

- Independently driven and fed with extruded clods.

- Produces special shape bricks, blocks and tiles.

- Two models available. BPD has maximum block size of 380x305x105mm and can be fitted with a 560mm stroke for pressing stoppers or similar goods. BPE has a maximum block size of 610mm x 550mm x 150mm.

| MECHANICAL PRESSES | ||

|---|---|---|

| Press Model | Output ( Bricks per hour ) | Power Input ( KW ) |

| Brick Re-press M/c | Single – 1000 Double - 2000 | 5.5 |

| Tile Re-press M/c | Single – 1500 Double - 3000 | 5.5 |

| Granular Feed Press | 1300 | 7.5 |

| Friction Screw Press | BPD – 75 to 150 BPE – 30 to 60 | 5.5 7.5 |