SIDE CUTTER TYPE CTC MK4

- Basic design cuts bricks or hollow blocks from soft to medium stiff extruded column with maximum cross section of 305 X 230mm.

- Cuts measured length or ‘slug’ from extruded column, which is then pushed through a bank of wires depositing cut bricks at take-off position.

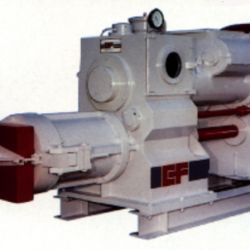

AUTOMATIC SIDE CUTTER TYPE CTOE

- Includes Slug Cutter to pre-cut extruded column to required length.

- Extruded clod is conveyed to side pusher cutting section where it is pushed through a bank of wires. Single or double sided delivery is possible.

- Fully automatic machine for high output of bricks or blocks.

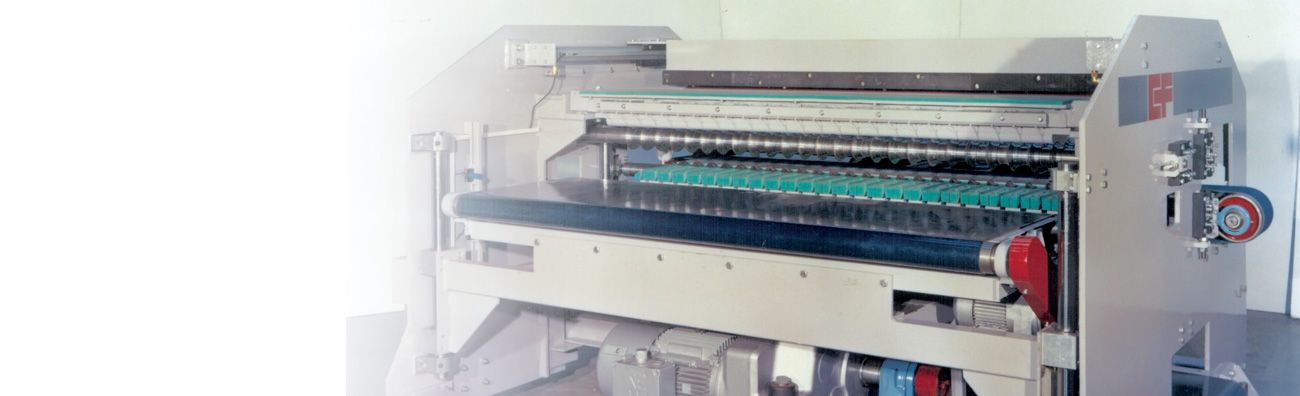

SERIES 2000 BRICK AND PAVER CUTTER

- Highly efficient machine for production of standard and modular bricks or chamfered pavers.

- Slug cutter pre-cuts the extruded column which is transferred to the main cutting section. A lift table with support platens lifts the column through a bank of wires.

- Heavy duty machine for stiff extruded product ( up to 4 to 5 penetrometer reading ).

ROTARY PELLET CUTTER ATTACHMENT

- For producing and cutting small pellets of clay, bentonite and other materials.

- With variable speed drive cutter it easily mounts onto front of extruder barrel.

| CUTTING TABLES | ||

|---|---|---|

| Cutter Ref. | Bricks per Hour | Power Requirement (kW) |

| CTC MK 4 Side Cutter | 1,500 to 4,000 | 2.8 |

| CTOE Side Cutter | Up to 13,000 – Single Sided Up to 18,000 – Double Sided | 7.5 |

| Series 2000 Brick & Paver Cutter | 15,000 to 20,000 | 12 |

| Rotary Pellet Cutter | Variable | 7.5 |