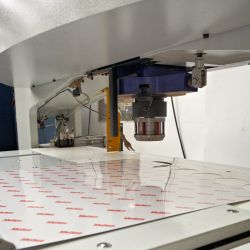

The New Concept Rhodes Stagger Feed Press has been designed to offer unrivalled production flexibility as a priority for today’s “just-in-time” world.

The Stagger Feed’s unique ability to blank, form and draw components makes the press ideal for producing lids and tops. Offering a rigid fabricated frame capable of withstanding the rigors of rapid stamping, the Stagger Feed Press can operate at up to 240 strokes per minute.

The press incorporates a fabricated steel frame optimised for maximum strength with minimum deflection, designed utilising the latest FEA software techniques. An AC variable speed motor, driving a dynamically balanced, quill mounted flywheel supported on heavy duty roller bearings ensures smooth operation of the crank slider mechanism. The slide is constructed of a high tensile high-grade aluminium alloy to give maximum strength and minimum weight. A fully automatic CNC controlled two axes sheet feed system is rigidly fixed to the press frame to ensure complete press/feeder repeatability. The press is controlled by a customised Rhodes Adaptive Motion control system incorporating the latest Siemens software.

| Pressure | 20 tonnes |

|---|---|

| Stroke | 140 mm. |

| Press Speed, variable | 240 spm maximum. |

| Maximum Sheet Size | 1200 mm x 1200 mm |

| Maximum Blank Size | 140mm Diameter |

| Slide Adjustment | 50 mm. |

| Bedplate to Slideface | 460 mm stroke up/adjustment up. |

| Main Frame | Steel fabrication. |

| Drive | Mechanical, direct flywheel drive. |

| Variable speed | AC Inverter. |

| Clutch/Brake | Ortlinghaus pneumatic. |

| Slide | Mounted in linear precision guides. |

| Die Cushion Force | 18KN |

| X/Y axis | Servo motor drive, precision guides, rotary encoders. |

| Sheet grippers | Pneumatic. |

| Sheet locations | Top and Side. |

| Control | Siemens PLC, 17” Touch Screen. |

| Guards | Sheet metal guards for motor drive etc. Mesh guards around tool space |

| Optional Extras include: | Automatic Sheet Feed: Pneumatic or Spring Cushion: Air Blast System. |