Conveyor Pulleys - Solid (tubular) Design

Hallamshire is a major UK supplier of Conventional Conveyor Pulleys and rollers.

Hallamshire is a major UK supplier of Conventional Conveyor Pulleys and rollers.

These can be manufactured to customer specification or alternatively Hallamshire will provide a suitable design for the application being considered. Our design department is always available to undertake full design calculations based on the provision of the conveyor design parameters by the customer – please contact our engineering personnel for more detail. Pulleys are supplied with either a crowned or flat profile. Slight crowning during the final machining process aids belt tracking and over tensioning of the belt edges.

Adverse weather conditions, insufficient angle of wrap, and many other effects can increase the possibility of slippage between pulley and belt (usually the drive pulley). In these instances wear to the pulley itself is more likely to occur and therefore a wide range of pulley coverings is offered i.e. Natural rubber – either plain or diamond pattern, Nitrile, Ceramic inserts and others. These increase the coefficient of friction at the pulley to belt interface and improve wear and slippage influences.

As with all Hallamshire products well proven designs and manufacturing processes ensure that they are capable of withstanding high belt tensions and shock loads. Some customer applications dictate the use of stainless steel, or special paint finishes / coatings, which can all be incorporated into their production.

Summary.

- Quality designed, manufactured, bespoke conveyor pulley’s.

- Fully welded fabricated design (with the exception of shaft fixture – customer specified)

- Choice of rubber coverings – if required.

- Competitive prices.

Conveyor Pulleys - Spiral Design

Hallamshire is the original designer and manufacturer of the ‘ Whittington’ Spiral Wound Conveyor Pulley. These were developed for use in situations where the self-cleaning and self-tracking features of the opposing spirals can be considered to be advantageous. As with conventional, tubular, pulleys these are supplied with either a crowned or flat profile.

Hallamshire is the original designer and manufacturer of the ‘ Whittington’ Spiral Wound Conveyor Pulley. These were developed for use in situations where the self-cleaning and self-tracking features of the opposing spirals can be considered to be advantageous. As with conventional, tubular, pulleys these are supplied with either a crowned or flat profile.

In situations where conventional pulleys suffer due to a build-up of material between the belt and the pulley (leading to costly belt, bearing or other damage) the spiral pulley is the correct choice. The spirals scrape the material off the back of the belt and into the pulley cage area from where it is displaced to the outside of the pulley and harm's way. Extra deflector plates can also be fitted to ensure a more positive discharge if required.

Well proven designs and manufacturing processes are used in the production of these pulleys and they are capable of withstanding high belt tensions and shock loads. Some customer applications dictate the use of stainless steel or special paint finishes / coatings, which can all be incorporated into their production.

Summary.

- Self-cleaning action of opposing spirals.

- Material removed from the belt under surface during operation.

- Optional deflector plates for improved material displacement.

- Assist belt with centring and tracking due to the action of the spirals.

- Prices are competitive with conventional tubular pulleys.

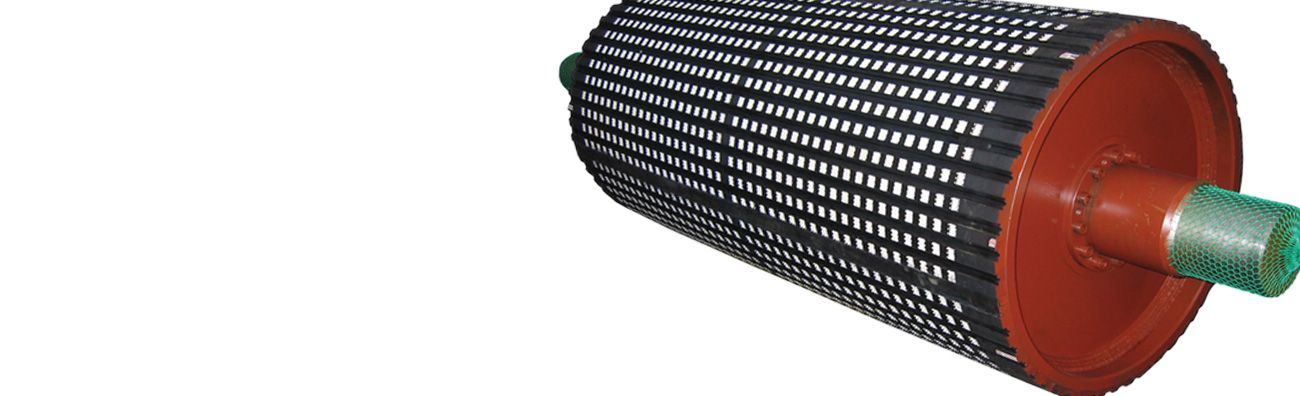

Conveyor Pulleys - Slatted Design

As an extension to our range of Spiral Wound Conveyor Pulley's Hallamshire has developed the Slatted Pulley for use in situations where there is a preference for a self-cleaning action but where the application is not conducive to the use of a Spiral pulley. As with conventional and spiral pulleys, the slatted design is supplied with either a crowned or flat profile.

As an extension to our range of Spiral Wound Conveyor Pulley's Hallamshire has developed the Slatted Pulley for use in situations where there is a preference for a self-cleaning action but where the application is not conducive to the use of a Spiral pulley. As with conventional and spiral pulleys, the slatted design is supplied with either a crowned or flat profile.

The construction of slatted pulleys lends itself to the incorporation of optional deflector plates to ensure a more positive discharge if required. Well proven designs, materials and manufacturing processes are used to ensure durability and long service and to meet the needs of applications that dictate the use of stainless steel, or special paint finishes / coatings.

Summary.

- Self-cleaning action.

- Material removed from the belt under surface during operation.

- Optional deflector plates for improved material displacement.

- Quality designed, manufactured, bespoke conveyor pulley’s.

- Fully welded fabricated design (with the exception of shaft fixture – customer specified)

- Competitive prices.