The Fielding and Platt range of concrete presses are specifically designed for producing high quality concrete products by either the Semi-Dry Mix Process or Wet Mix Process.

Ancillary products, such as Take-Off Edge Stacking Units (illustrated right) and automatic Mould Filling systems (below) are available to complement the full range of Fielding and Platt concrete presses.

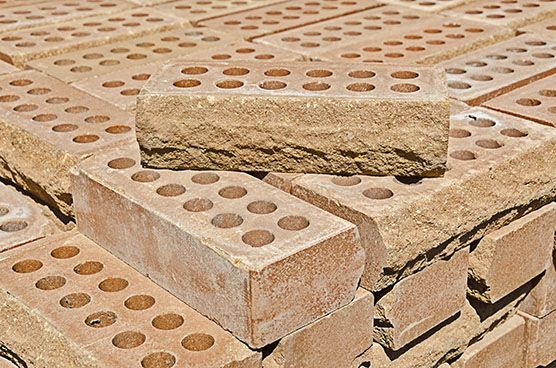

Block Making Machinery using the Semi-Dry Mix process ensures high production output with low unit costs, and is a process suitable for most aggregates. Compaction is by vibration combined with hydraulic pressure to give consistent results and optimum cement usage. Fielding and Platt Wet Mix concrete presses are ideal for the manufacture of high-strength, high-density concrete products to close tolerances. Single station and three station presses utilise the Fielding Wet-Pressed Process to ensure long product life and an excellent surface finish.