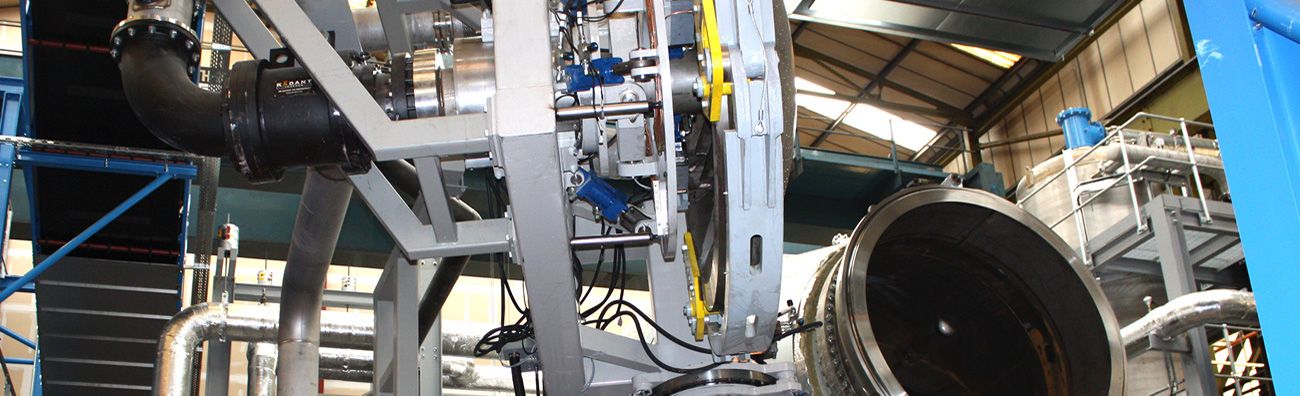

Rhodes Autoclaves offer unrivalled expertise in the supply of autoclaves and ovens. Our machinery produces precision-engineered composite products for leading aerospace and automotive manufacturers worldwide.

The quest for lighter and faster aircraft, high performance motor vehicles and corrosive resistant ships, has lead to an increase both in the size and sophistication of autoclaves. Rhodes Autoclaves embrace the opportunities presented by modern day industry with a state-of-the-art product range.

Fabricated utilising the latest welding techniques and highly sophisticated computerised control systems, Rhodes autoclaves achieve precise three dimensional, uniform pressures of greater than 1 bar to enable the production of an infinite variety of different shapes and sizes.

Key Features of Rhodes Environmental Autoclaves Include:

Safety Systems

In accordance with The UK Health and Safety Executive’s Guidance Note PM73 ‘Safety at Autoclaves’, all Rhodes Autoclaves are fitted with Safety Devices to:

- Ensure the autoclave cannot be pressurised without the door being fully locked

- Ensure the autoclave door cannot be opened until the pressure has safely vented

- Warn the operator of any residual pressure, prior to door opening

- Prevent the autoclave from opening violently due to residual low pressure

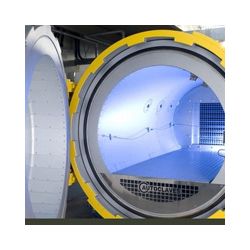

Temperature Control

Rhodes Autoclaves utilise either direct or indirect heating systems to achieve a uniform temperature inside the autoclave. Indirect heating systems provide the heat source outside the autoclave and transfer heat into the working envelope by means of a heat exchanger. Direct heating systems have their heat source within the autoclave and aim to maximise the heat transfer from the elements to the pressure medium. Temperature profiles are generally made up of a series of heating gradients, dwells and cooling gradients. Electrically heated and gas heated systems are also available.

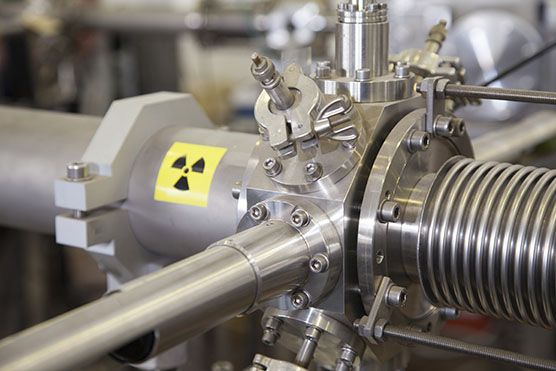

Pressurisation Control

Rhodes Autoclave systems are designed to allow the user to set the internal pressure conditions to the required level at any time during the cure cycle. As in temperature control, this generally takes the form of a series of pressurisation gradients, dwells and de-pressurisation gradients. Accurate control is achieved through the use of modulating valves on the inlet and exhaust pipework systems of the autoclave.

Safety is of paramount importance, when working with pressurised systems. Strict design codes (eg. PD5500, ASME) are met to ensure the necessary safety margins are in place.

Vacuum Control

The bagged composite lay-up arrives at the autoclave with a vacuum already drawn. The bag is then connected to the autoclave vacuum system via flexible umbilical hoses fitted inside the autoclave. During the cure cycle the vacuum level in each bagged component is monitored and in the event that a leak or burst condition occurs, the offending bag is automatically isolated from the rest of the vacuum system, thus preventing positive pressure from entering other bags via a common manifold.

During the cure process, volatile substances are created within the bag. These are drawn away by the vacuum system and filtered out by a resin trap fitted in the main vacuum draw line. Systems are available with the facility to vary the level of vacuum drawn within the bag. This is of particular relevance when honeycomb structures are being produced.

Computerised Process Control, Monitoring and Data Logging

Rhodes Autoclaves are supplied with a PC and SCADAsoftware. These enable the user to monitor the cure parameters in real-time both for data-logging purposes and also for cure optimisation. This results in reduced cure cycle times, while maintaining product quality and repeatability.

Ancillary Equipment

- Vacuum Fittings and Hoses

- Vacuum plugs and sockets